- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

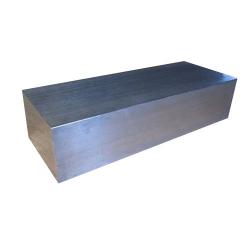

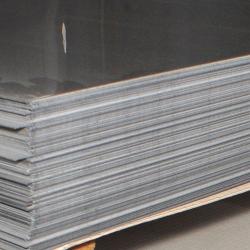

Polished Stainless Steel Sheets

Product Code : MET100027

Brand : MetlineCategory: Metals, Alloys and Minerals

Price : 200.00 198.00

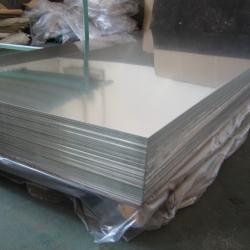

In addition to our inventory of #4 and #8 mirror finish sheet, Penn Stainless can provide a number of custom options to meet specific customer requirements including polishing both sides of the sheets, long grain finishes, non-directional stainless steel sheet finishes, #6 finish, #7 finish or per customer request.

Stainless steel plate polishing is an important process for manufactures and architectural applications. Polishing stainless steel plates creates a uniform and consistent surface finish–vital for tank manufactures and OEMs supplying products to the chemical and pharmaceutical industries. Penn Stainless inventories polished sheet, plate and some structural items in #4 finish and a #8 mirror finish.

The stainless steel is cold rolled, softened and descaled, similar to the process of a 2D finish. It then receives a final light pass on polished rolls known as a ‘pinch pass’. The steel remains gray in appearance, but the final pass on polished rolls produces a smoother, brighter surface than 2D finish. This is a general purpose, cold rolled finish; it is suitable for a wide range of stainless steel applications and wide range of subsequent polishing processes, such as satin finishing. Typical uses for 2B finish include non-decorative or functional sheet metal products, industrial refrigeration equipment, chemical plant and plumbing fixtures.