- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

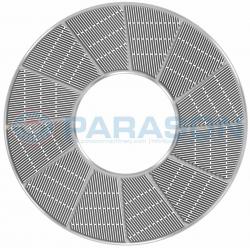

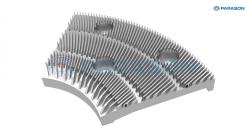

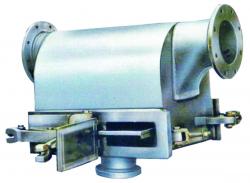

High consistency System For Pulp & Paper Making Machine

Product Code : PM-28

Brand : Parason machinery

Store Number :

2406644444

(Click to call)

Category: Industrial Plant and Machine

Price : 10.00 431001.00

High consistency System - For Pulp & Paper Making Machine

Application & Salient Feature

Excellent Defiberizing: Fiber to fiber friction creates excellent defiberizing and maintained the fiber length in original size. (almost uncut)

Easy Separation Of Fibers & Contaminants: Minimal breakdown of contaminants such as plastics, films, adhesives, hot melts, etc. helps easy removal in next cleaning stage. Helps De-Inking: Efficient fiber to fiber friction separates ink, pigments binders etc. with the help of chemicals in pulper. Energy Saving: Energy transfer is used skillfully by friction between fibers due to perfectly correct surface contours of flight. And also utilization higher consistency (15 to 16%) This energy consumed subsequently reduces power in proceeding process.