- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

Hi Consistency Pulper (rotor) for Pulp and Paper Machine

Product Code : PM-12

Brand : Parason machinery

Store Number :

2406644444

(Click to call)

Category: Industrial Plant and Machine

Price : 10.00

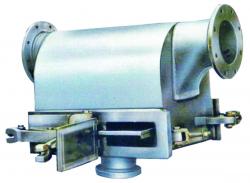

Hi Consistency Pulper- For Pulp and Paper Making Machine

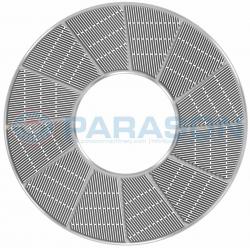

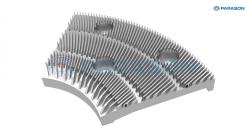

High Consistency Pulper is used for breaking waste paper in high consistency. The rotor combines triple flighted & dentiform fly bar & produces intenses fiber to fiber friction, so it can speed the defibering of the waste paper.

Application & Salient Feature

Excellent Defiberizing Fiber to fiber friction creates excellent defiberizing and maintained the fiber length in original size. (almost uncut)

Easy Separation Of Fibers & Contaminants Minimal breakdown of contaminants such as plastics, films, adhesives, hot melts, etc. helps easy removal in next cleaning stage. Helps De-Inking Efficient fiber to fiber friction separates ink, pigments binders etc. with the help of chemicals in pulper. Energy Saving Energy transfer is used skillfully by friction between fibers due to perfectly correct surface contours of flight. and also utilization higher consistency (15 to 16%) This energy consumed subsequently reduces power in proceeding process.

Features

Mainly used for separating waste paper and ink under high consistency in waste paper deinking process.

Special spiral rotor effectively promote the circulation and rollover of pulp, reinforce friction between fibers. Finally achieve gentle pulp under high consistency, impurities will not be broke in the process of fiber relief and deinking,

Dealing with 12%-18% high consistency pulp, effective chemical mixture and friction between fibers under high consistency make the ink particle separate from the surface of fiber fully.

Compact structure, convenient operation and maintenance.