- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

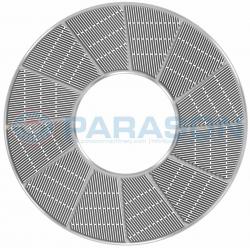

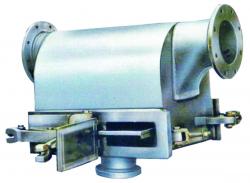

Centricleaner for Pulp & Paper Machine

Product Code : PM-23

Brand : Parason machinery

Store Number :

2406644444

(Click to call)

Category: Industrial Plant and Machine

Price : 10.00

Centricleaner

Application & Salient Feature

Parason Centricleaners are designed to remove air, dirt, shives and specks from pulp stock efficiently and economically. Its smooth internal surface and small diameter ensure outstanding performance.

Benefits

- Efficient removal of contaminants like sand, glass, chips, pins etc. from the pulp stock.

- Efficient removal of impurities like dirt, shives and specks.

- Simple installation.

- Improved optical cleanliness of paper due to removal of specks shives & dirt.

- The small cone diameter resulting in outstanding cleaning efficiency.

- SS- 304 Construction.

Working Principles

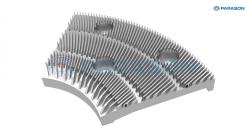

Pulp stock at 0.5 to 1.0% Consistency enters the tangential inlet Which accelerates the stock to downward centrifugal motion. Contaminants like dirt, shive and specks with high specific gravity are forced to outer wall of cone and downward through reject outlet orifice. Rejects are collected in a tank which is again fed to the 2nd stage of cleaning. The cleaned pulp stock rises through center of bottle toward the accept outlet.

Technical Specification

- Operating Consistency % - 0.5 to 1.0%

- Position - Applicable for pulp mill and approach flow system.

- Throughput - 500 Ipm to 1000 Ipm