- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

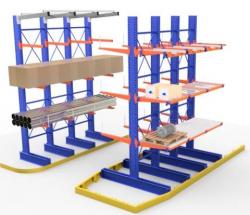

Drive in racking system is an assembled racking which forklift truck drives into the racking to store goods in pallet units. Drive in racking system is a kind of racking with high storage density, its space efficiency utilization rate can reach 90%, the site area utilization rate can reach more than 60%, suitable for the storage of large quantities of goods with few varieties.

The vertical orientation of the drive in racking only relies on the top beam and bracing to connect the system as a whole. The depth direction of the racking is mainly through the combination of the support and pallet rail for placing the pallet goods, so as to connect the frame into a whole. Drive in racking system is mainly assembled by frame, guide rail, support, pallet rail, top beam & top bracing, back beam & back bracing and protector, etc.

Drive in rack can be divided into one direction and two direction arrangement according to the direction of picking the goods. One direction (by the wall area) is best controlled within 6 pallet depths. The overall depth of the racking area is best controlled within 12 pallet depths to improve the efficiency and reliability of the forklift access.

Forklift truck is a continuous "high lift" operation mode. Forklift truck is easy to shake and bump into the rack, so the stability consideration is essential. The stability of this kind of storage system is weak, the rack is not too high, it should be controlled within 10 meters, and in order to strengthen the stability of the whole racking system, except for the size and selection of the system, the pull and solid device must be added. Single cargo should not be too large and too heavy. Usually the weight is controlled within 1500KG, and the span of pallets should not exceed 1.5 meters. Forklift trucks are often used as forklift trucks or counterbalanced battery forklifts.

https://www.jracking.com/drive-in-rack/